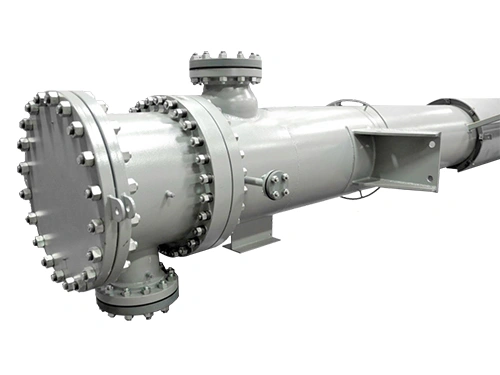

Shell and Tube Heat Exchanger (Tantalum)

The tantalum shell and tube heat exchanger combines the alloy’s exceptional corrosion resistance with the versatility of the shell-and-tube design. It is developed to withstand some of the most aggressive chemical environments while maintaining stable operation, making it a practical replacement for conventional metal or non-metal exchangers in high-end chemical and pharmaceutical processes. By delivering extreme corrosion protection, efficient heat transfer, and long service life, it ensures reliability in applications where other materials cannot perform.

The tantalum shell-and-tube heat exchanger is recommended when:

- The heat transfer medium involves highly corrosive acids such as concentrated hydrochloric acid, nitric acid, aqua regia, or mixed acids, where titanium and Hastelloy are no longer suitable. Hydrofluoric acid and fuming sulfuric acid, however, require specialized materials.

- Ultra-high purity is required, such as in pharmaceutical APIs or electronic chemicals, where zero metal ion contamination is critical, and continuous stable operation is needed to avoid frequent maintenance of non-metallic exchangers.

- Conditions involve moderate temperatures and pressures (from -200 °C to 250 °C, up to 8 MPa), and the operating budget allows for tantalum’s higher cost. Due to its expense, tantalum is generally reserved for environments where no other material can provide adequate resistance.

Our engineers provide expert guidance on corrosion-resistant glass-lined reactors, tanks, and customized process equipment for chemical, pharmaceutical, and industrial applications.

Jiangsu Gongtang

Jiangsu Gongtang