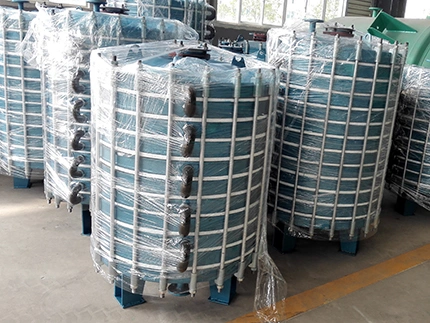

Glass Lined Heat Exchanger

Corrosion-resistant condensers for chemical, pharmaceutical, and industrial applications

Heat exchangers are used to transfer heat between two media without mixing them. In industries such as chemicals, pharmaceuticals, and petrochemicals, they have an important role in various processes including heating, cooling, or condensing fluids under demanding conditions. In processes where the equipment is exposed to aggressive media, glass lined heat exchangers help prevent corrosion and ensure long-term stability.

Glass lined heat exchangers are available in two main designs: plate type and multi-tube type. Both designs combine the strength of steel with the protective glass lining, which is suitable for industrial incinerators, flue gas desulfurization units, and other applications that demand reliable heat transfer in corrosive environments. To ensure durability, the tubes inside the heat exchangers are coated using an electrostatic powder process that guarantees a consistent glass lining. The coating is continuously monitored to achieve the proper thickness and eliminate pores, providing reliable protection against corrosion.

The glass lined plate heat exchanger is designed for condensing and cooling highly corrosive fluids and is widely used in chemical, pharmaceutical, pesticide, and light industries. When fitted with food-grade rubber gaskets, it can also be applied in food processing.

View MoreIn chemical and pharmaceutical plants, processes such as boiling, condensation, and heat transfer often involve corrosive or demanding media. Glass lined shell and tube heat exchangers are built to meet these challenges by combining a steel shell, which provides the strength to withstand pressure, with glass-lined tubes that resist corrosion and maintain a smooth, non-reactive surface.

View More

How are the tubes in glass lined heat exchangers treated, and how is quality controlled?

The tubes are coated using an automatic electrostatic powder spraying process. During production, sensors track the entire coating process in real time, making sure the glass layer is evenly applied, has the right thickness, and contains no pores. This level of control makes sure the coating lasts longer and the equipment runs safely.

What types of glass lined heat exchangers can be supplied?

Glass lined heat exchangers are available in two main types: plate type and multi-tube type. Plate heat exchangers are compact and easy to maintain, while multi-tube heat exchangers are ideal for handling larger volumes. Both types of heat exchangers can deliver efficient heat transfer and strong resistance to corrosion in chemical and related industries.

What structural options are available for plate heat exchangers?

Plate models come in two versions: circular plate condensers and square plate condensers. Each design can be selected depending on the space available and the process conditions.

What are the advantages of plate heat exchangers in terms of installation, maintenance, and service life?

Plate exchangers are modular in design. They are easy to assemble and take apart, and if one plate is damaged, it can be replaced on its own. This not only simplifies maintenance but also helps extend the overall service life of the unit.

How do glass lined multi-tube heat exchangers perform compared to regular plate exchangers?

Glass lined multi-tube heat exchangers provide much better heat transfer efficiency compared to regular plate exchangers. They also overcome common problems of plate designs, like slower flow rates, risk of enamel cracking, and poor performance under vacuum conditions.

Jiangsu Gongtang

Jiangsu Gongtang