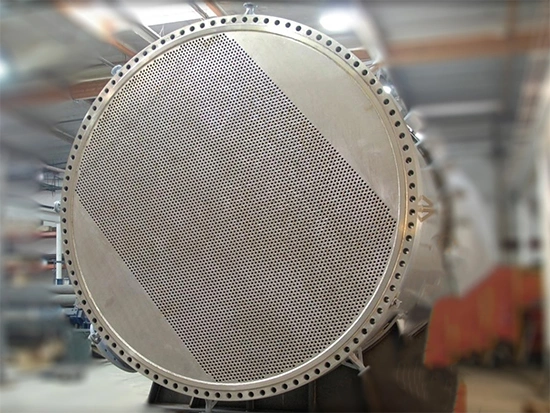

Shell and Tube Heat Exchanger (Titanium)

The titanium shell and tube heat exchanger brings together the alloy’s strong corrosion resistance with the adaptability of the shell-and-tube design. It is engineered to handle corrosive heat transfer media while ensuring stable operation, making it a dependable alternative to stainless steel exchangers in industries such as chemicals and metallurgy. By balancing corrosion protection, heat transfer efficiency, and compatibility with a wide range of operating conditions, it supports long-term, reliable use in demanding environments.

The titanium shell-and-tube heat exchanger is best suited for the following conditions:

- Heat transfer media such as dilute acids, organic acids, saline solutions, or seawater, where 316L stainless steel has already shown corrosion, provided strong reducing acids like concentrated hydrochloric or hydrofluoric acid are not present (Hastelloy is recommended in such cases).

- Continuous and stable heat transfer requirements, for example in chemical plants or pharmaceutical production lines, where ease of maintenance is important. The shell-and-tube design allows individual tube replacement, reducing costs compared to full titanium plate heat exchangers.

- Applications with relatively stable temperature and pressure ranges (from -50 °C to 250 °C, and up to 10 MPa). For service above 250 °C, nickel-based alloys are preferred, while pressures exceeding 10 MPa require specially designed titanium equipment.

Our engineers provide expert guidance on corrosion-resistant glass-lined reactors, tanks, and customized process equipment for chemical, pharmaceutical, and industrial applications.

Jiangsu Gongtang

Jiangsu Gongtang