These corrosion resistant columns meet GB25025-2010 or ASME standards, ensuring reliable performance and compliance with industry requirements. The design brings together the chemical inertness of glass with the strength of a steel structure, resulting in equipment that is both durable and resistant to corrosion.

Besides the standard glass lined column models, customized solutions can be provided, including distillation, extraction, and absorption columns, as well as other glass lined process equipment tailored to specific operating conditions.

Features

- Glass lined columns can handle a wide range of corrosive media, including strong acids, oxidizing agents, and organic solvents. The only limitation is with solutions that contain fluorine ions, which are not suitable.

- The inner glass surface is smooth and non-porous, making it resistant to staining and much easier to clean compared to bare metal.

- Because the lining is impermeable, it prevents cross-contamination between batches. At the same time, the chemical stability of glass keeps the purity, color, and properties of the stored or processed materials intact.

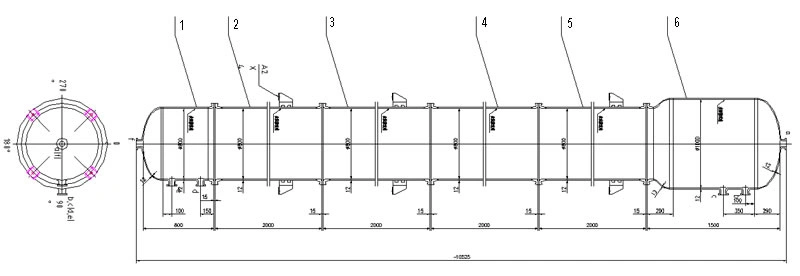

Technical Parameters

| Design temperature | 0℃~+200℃ |

| Design pressure | Column interior | FV-0.25MPa |

| Jacket | 0.6MPa |

| DN | D

(mm) | Max. length L

(mm) | Max. section length L1

(mm) | Assembly method |

| 200 | 219 | 3000 | - | Assembled with split flange |

| 250 | 273 | 3000 | - |

| 300 | 325 | 3000 | 500 |

| 400 | 406 | 3000 | 750 | Assembled with clamps |

| 500 | 508 | 3000 | 1000 |

| 600 | 600 | 4000 | 1400 |

| 800 | 800 | 4500 | 2000 |

| 1000 | 1000 | 4500 | 2500 |

| 1200 | 1200 | 6000 | 4000 |

| 1400 | 1400 | 6000 | 4000 |

| 1600 | 1600 | 6000 | 4000 |

| 1800 | 1800 | 6000 | 4000 |

| 2000 | 2000 | 6000 | 4000 |

Note: Nozzles and accessories for the columns can be customized based on specific customer requirements.

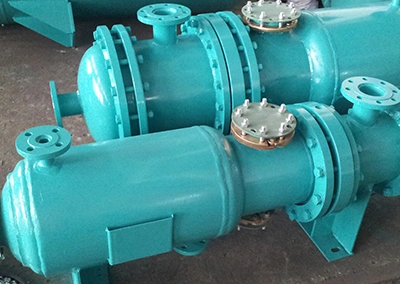

Glass Lined Columns in Operation at Customer Site

Jiangsu Gongtang

Jiangsu Gongtang