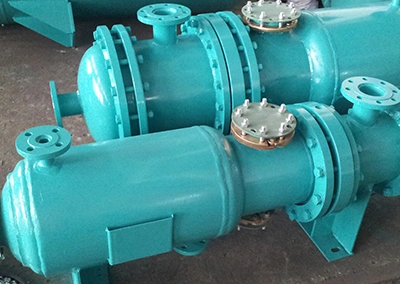

Horizontal glass lined storage tanks are designed to handle the demanding conditions of industries where corrosive materials are stored. The shell is built from carbon steel, providing the structural strength needed for industrial use. Inside, a layer of enamel is fused to the steel at high temperatures, forming a smooth and chemically stable surface. This enamel lining prevents direct contact between the stored medium and the metal, reducing the risk of contamination and extending the service life of the tank. By combining strength and corrosion resistance, these storage tanks can safely store a wide range of aggressive chemicals while maintaining reliable performance.

These tanks are produced in capacities from 50L to 200,000L, with a maximum design pressure of 0.6 MPa. They can safely store media within a temperature range of 0 °C to 150 °C, covering the needs of many chemical processes. By combining strength, resistance, and adaptability, horizontal glass lined storage tanks have become a dependable choice for long-term industrial use.

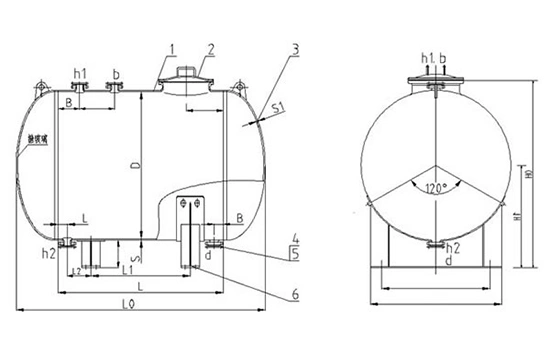

Dimensional Drawing

Note:

- 1. Tank body

- 2. Glass-lined manhole

- 3. Elliptical head

- 4. Type A glass-lined nozzle

- 5. Lap joint flange

- 6. Saddle support

Dimensions of Horizontal Glass Lined Storage Tanks, 3000L-12500L (mm)

Nominal volume

VN/L | L0 | L1 | L2 | L3 | L4 | H1 | H | A1 | K1 | A2 | B | E | F | A3 |

| 3000 | 2710 | 900 | 310 | 403 | 250 | 1760 | 1000 | 1350 | 1120 | 200 | 100 | 490 | 100 | 570 |

| 4000 | 3310 | 1500 | 310 | 403 | 250 | 1760 | 1000 | 1350 | 1120 | 200 | 100 | 490 | 120 | 550 |

| 5000 | 3265 | 1240 | 480 | 440 | 250 | 2080 | 1200 | 1430 | 1180 | 350 | 150 | 300 | 150 | 300 |

| 6300 | 4060 | 1740 | 580 | 440 | 250 | 1980 | 1200 | 1430 | 1180 | 350 | 150 | 600 | 150 | 600 |

| 10000 | 4080 | 1820 | 415 | 550 | 160 | 2340 | 1300 | 1780 | 1490 | 250 | 150 | 950 | 150 | 950 |

| 12500 | 4800 | 2740 | 470 | 649 | 260 | 2340 | 1300 | 1780 | 1490 | 250 | 150 | 950 | 150 | 950 |

Nozzle Specifications (mm)

Nominal volume

L | Actual volume

L | Diameter | Tank | Head thickness

S1 | Nominal diameter of nozzles (DN) | Liquid level gauge

length ×quantity |

Tank wall thickness

s | Length

L | Spare nozzle

a | Spare nozzle

b | Spare nozzle

c | Outlet nozzle

d | Liquid level gauge

e1, e2 | Inlet nozzle

f | Outlet nozzle

h | Process nozzle

g |

| 3000 | 3490 | 1450 | 14 | 1550 | 14 | 65 | 125 | 65 | 65 | 65 | 65 | 65 | 600 | 1000×1 |

| 4000 | 4500 | 1450 | 14 | 2150 | 14 | 65 | 125 | 65 | 65 | 65 | 65 | 65 | 600 | 1000×1 |

| 5000 | 5680 | 1600 | 16 | 2200 | 16 | 100 | 80 | 80 | 65 | 65 | 80 | 80 | 600 | 1200×1 |

| 6300 | 7100 | 1600 | 16 | 2900 | 16 | 100 | 65 | 65 | 65 | 65 | 80 | 80 | 600 | 1200×1 |

| 10000 | 10860 | 2000 | 20 | 2700 | 20 | 100 | 100 | 150 | 100 | 65 | 100 | 100 | 800 | 1300×1 |

| 12500 | 13921 | 2000 | 20 | 3680 | 20 | 100 | 100 | 150 | 100 | 65 | 100 | 100 | 800 | 1300×1 |

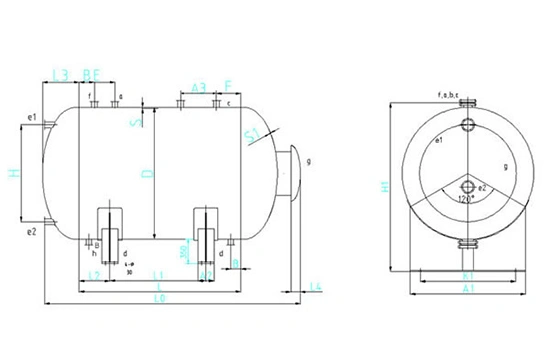

Dimensions of Horizontal Glass Lined Storage Tank, 16000L-80000L

Nominal volume

VN/L | Actual volume

V/L | Diameter

D | Tank | Head thickness

S1 | Nominal diameter of nozzles DN | L0 | L | L1 | L2 | H0 | H1 |

Wall thickness

S | Length

L | Inlet

b | Spare nozzle

d |

| 16000 | 17756 | 2200 | 20 | 3840 | 20 | 150 | 150 | 5080 | 2840 | 450 | 142 | 2900 | 1470 |

| 20000 | 22330 | 2400 | 22 | 4030 | 22 | 150 | 150 | 5374 | 2930 | 500 | 140 | 3110 | 1572 |

| 25000 | 27790 | 2800 | 24 | 3480 | 24 | 150 | 150 | 5028 | 2280 | 600 | 238 | 3510 | 1774 |

| 30000 | 33300 | 3000 | 26 | 3630 | 26 | 150 | 150 | 5282 | 2370 | 630 | 236 | 3720 | 1876 |

| 40000 | 44000 | 3200 | 28 | 4300 | 28 | 200 | 200 | 6060 | 2800 | 650 | 234 | 3900 | 1978 |

| 50000 | 55000 | 3400 | 30 | 4830 | 30 | 200 | 200 | 6690 | 3230 | 700 | 232 | 4100 | 2080 |

| 63000 | 69000 | 3600 | 32 | 5480 | 32 | 200 | 200 | 7440 | 3780 | 750 | 230 | 4300 | 2182 |

| 80000 | 88000 | 3800 | 34 | 6390 | 34 | 200 | 200 | 8460 | 4590 | 800 | 228 | 4500 | 2284 |

Jiangsu Gongtang

Jiangsu Gongtang