The overall performance of these storage vessels depends on both external and internal quality. External quality can be evaluated through visual inspection and instrument testing, while internal quality is determined by the accuracy of forming, welding, and surface treatment, as well as by how strictly each production stage is controlled.

Any defects, whether visible or microscopic, can appear during transportation, storage, or operation, which may lead to equipment failure. The reliability of the tank depends on keeping every step of production under control, whether it’s forming, welding, or surface treatment.

These tanks use high-quality enamel coatings that make them durable, bringing together the strength of steel and the protective qualities of glass. Careful control at every stage of production helps keep the quality consistent and extends their service life.

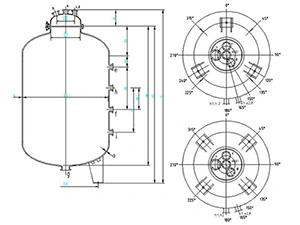

Dimensions of Close Type Glass Lined Storage Tanks

Nominal volume

VN/L | DN | D1 | D2 | D3 | D4 | H | H1 | H2 | H3 | H4 | H5 | H6 | H7 | H8 | S |

| 3000 | 1600 | 600 | 420 | 30 | 1200 | 2740 | 300 | 2422 | 550 | 115 | 1000 | / | / | 2220 | 16 |

| 5000 | 1600 | 600 | 420 | 30 | 1200 | 3720 | 305 | 3400 | 520 | 130 | 1200 | 460 | 1200 | 3160 | 16 |

| 6300 | 1750 | 600 | 420 | 30 | 1225 | 3924 | 310 | 3604 | 580 | 130 | 1200 | 424 | 1200 | 3304 | 18 |

| 8000 | 2000 | 700 | 490 | 36 | 1500 | 3880 | 340 | 3520 | 630 | 150 | 1100 | 500 | 1100 | 3280 | 20 |

| 10000 | 2200 | 700 | 490 | 36 | 1520 | 4053 | 340 | 3703 | 692 | 150 | 1200 | 600 | 1200 | 3392 | 20 |

| 20000 | 2600 | 700 | 490 | 36 | 1820 | 5540 | 340 | 5200 | 665 | 150 | 1800 | 600 | 1800 | 4605 | 24 |

| 30000 | 2800 | 700 | 490 | 36 | 1960 | 6090 | 340 | 5750 | 710 | 150 | 1800 | 600 | 1800 | 5510 | 26 |

| 40000 | 3200 | 800 | 480 | 36 | 2400 | 6870 | 386 | 6474 | 965 | 150 | 2200 | 500 | 2200 | 6125 | 28 |

| 50000 | 3400 | 800 | 480 | 36 | 2720 | 7500 | 386 | 7124 | 975 | 150 | 2600 | 570 | 2600 | 6630 | 32 |

Nozzle Specifications (mm)

Nominal volume

VN/L | a | b | c | d | e1-2 | h1-2 | g |

| 3000 | 125 | 65 | 65 | 65 | 65 | 65 | 125 |

| 5000 | 125 | 65 | 65 | 65 | 65 | 65 | 125 |

| 6300 | 125 | 65 | 65 | 65 | 65 | 65 | 125 |

| 8000 | 125 | 80 | 65 | 65 | 80 | 80 | 125 |

| 10000 | 125 | 80 | 65 | 65 | 80 | 80 | 125 |

| 20000 | 300×400 | 100 | 100 | 125 | 100 | 100 | 125 |

| 30000 | 300×400 | 100 | 100 | 125 | 125 | 125 | 125 |

| 40000 | 125 | 150 | 100 | 100 | 125 | 125 | 200 |

| 50000 | 125 | 150 | 100 | 100 | 125 | 125 | 200 |

Jiangsu Gongtang

Jiangsu Gongtang