6300L open type glass lined reactor with quick-opening manhole cover

Integrated frame glass lined reactor

Glass lined reactor with customized water connection system

Special structure glass-lined reactor with balance tank

Glass-lined reactor with fixed baffle

10000L open type glass lined reactor

In the open-type design, the lid and vessel body are separate parts. The connection between the lid and the vessel is sealed with a gasket and tightened with clamps, maintaining proper sealing throughout operation.

This type of reactor combines the stability and corrosion resistance of glass with the strength of steel. The interior surface is smooth, easy to clean, and resistant to impact, heat, abrasion, and chemical corrosion. Thanks to these properties, the open type glass lined reactor is suitable for operations such as hydrolysis, neutralization, crystallization, mixing, and emulsification.

Open-type glass lined reactors are widely used in industries including chemicals, petroleum, pharmaceuticals, pesticides, food, and dyes. They are available in a full range of specifications, and non-standard designs can also be produced according to customer requirements.

Technical Parameters

| Design pressure | Internal | Packing seal | 0.2MPa |

| Mechanical seal | 0.4MPa/1.0MPa |

| Jacket | 0.6MPa/0.8Mpa/1.0MPa |

| Design temperature | Internal | -19℃~+200℃ |

| Jacket | -19℃~+200℃ |

| Agitator speed | Anchor type, frame type | 63r/min |

| Oar type | 110r/min~130r/min |

| Impeller type | 110r/min~130r/min |

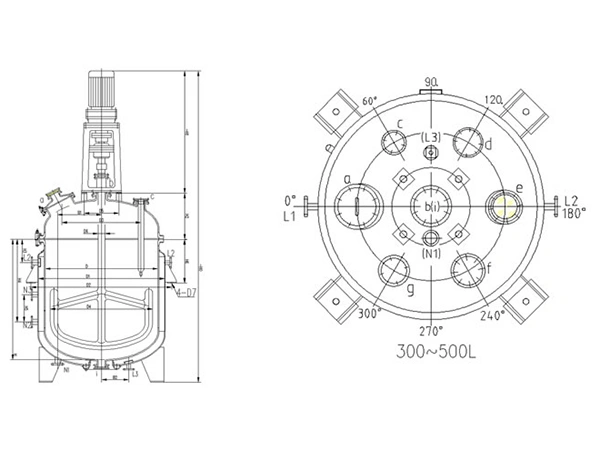

Dimensions of Open Type Glass Lined Reactors (mm)

| Volume (L) | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 5000 | 6300 | 8000 | 10000 |

| Item |

| D | 800 | 900 | 1200 | 1300 | 1300 | 1600 | 1600 | 1750 | 1750 | 2000 | 2000 |

| D1 | 900 | 1000 | 1300 | 1450 | 1450 | 1750 | 1750 | 1900 | 1900 | 2200 | 2200 |

| D2 | 1032 | 1148 | 1488 | 1639 | 1675 | 2044 | 2044 | 2218 | 2218 | 2500 | 2533 |

| D3 | 560 | 630 | 840 | 910 | 910 | 1120 | 1120 | 1225 | 1225 | 1400 | 1400 |

| D4 | 720 | 810 | 1080 | 1180 | 1180 | 1440 | 1440 | 1580 | 1580 | 1800 | 1800 |

| D5 | 350 | 350 | 400 | 400 | 400 | 450 | 450 | 450 | 450 | 510 | 510 |

| D6 | 65 | 65 | 80 | 80 | 80 | 95 | 95 | 95 | 95 | 110 | 110 |

| D7 | 23 | 23 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 36 | 36 |

| H | 800 | 1000 | 1200 | 1400 | 1745 | 1739 | 2700 | 2317 | 3025 | 3120 | 3460 |

| H0 | 2530 | 2759 | 3222 | 3440 | 3785 | 4073 | 5115 | 4792 | 5850 | 5450 | 6270 |

| H1 | 1050 | 1050 | 1240 | 1240 | 1240 | 1454 | 1535 | 1535 | 1535 | 1650 | 1700 |

| H2 | 380 | 409 | 482 | 500 | 500 | 580 | 580 | 640 | 640 | 720 | 710 |

| H3 | 260 | 270 | 300 | 330 | 330 | 330 | 330 | 330 | 330 | 420 | 355 |

| H4 | / | / | / | 960 | 1335 | 1242 | 2000 | 1490 | 1700 | 2000 | 2650 |

| H5 | / | / | / | / | / | / | 700 | 420 | 700 | 900 | 880 |

| H6 | 390 | 420 | 500 | 600 | 600 | 700 | 700 | 700 | 815 | 850 | 850 |

| B1 | / | / | / | 507 | 507 | 614 | 614 | 550 | 550 | 550 | 540 |

| B2 | 250 | 270 | 350 | 350 | 370 | 370 | 370 | 370 | 370 | 400 | 450 |

| Power (kW) | 1.5 | 3 | 4 | 4 | 4 | 5.5 | 7.5 | 7.5 | 11 | 11 | 11 |

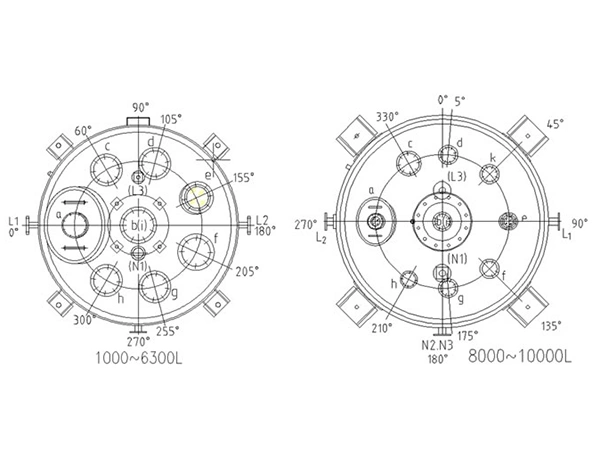

Nozzle Specifications (mm)

| Volume (L) | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 5000 | 6300 | 8000 | 10000 |

| Item |

| a | 125 | 150 | 300×400 | 300×400 | 300×400 | 300×400 | 300×400 | 300×400 | 300×400 | 300×400 | 300×400 |

| b | 100 | 100 | 125 | 125 | 125 | 150 | 150 | 150 | 150 | 200 | 200 |

| c | 65 | 65 | 100 | 100 | 100 | 100 | 100 | 125 | 125 | 200 | 200 |

| d | 80 | 80 | 100 | 100 | 100 | 100 | 100 | 125 | 125 | 150 | 150 |

| e | 65 | 100 | 100 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 |

| f | 65 | 125 | 125 | 125 | 125 | 125 | 125 | 150 | 150 | 125 | 125 |

| g | 65 | 100 | 100 | 100 | 100 | 100 | 100 | 125 | 125 | 150 | 150 |

| h | / | / | 100 | 200 | 125 | 125 | 125 | 150 | 150 | 125 | 125 |

| K | / | / | / | / | / | / | / | / | / | 150 | 150 |

| i | 80 | 80 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 125 | 150 |

| L1-L3 | 25 | 32 | 32 | 40 | 40 | 50 | 50 | 65 | 65 | 65 | 65 |

| N1, N2 | / | / | / | 50 | 50 | 50 | 65 | 65 | 65 | 65 | 65 |

| N3 | / | / | / | / | / | / | 65 | 65 | 65 | 65 | 65 |

Jiangsu Gongtang

Jiangsu Gongtang