When transporting unpackaged glass lined equipment, force must only be applied to the lifting lugs. Ensure that the coupler, clamps, and other vulnerable parts are not subjected to stress. The equipment must never be rolled or moved with crowbars, as this may cause serious damage. It is also essential to avoid shocks and collisions during handling.

When lifting glass lined equipment, the wire rope must be secured to the designated points such as the jacket nozzle or the tank lugs. The lifting rings on the tank lid are designed only for removing the lid and must not be used to lift the entire vessel. The equipment should always be hoisted smoothly and lowered gently, ensuring that it does not collide with other objects during handling.

Before starting assembly, the inspector should enter the vessel wearing clean, soft-soled shoes to avoid damaging the lining. Inside, check carefully that the glass surface is intact, with no cracks, scratches, or other defects that could affect performance.

Flange bolts must be tightened gradually and evenly. Work diagonally, tightening bolts in pairs to distribute the pressure. Never tighten one side all at once, as uneven force can crack the glass lining or cause hidden stress that shortens service life.

Check all clamps in advance to ensure they are undamaged and in the correct quantity. During installation, place clamps at equal intervals and tighten them evenly. Proper spacing and balanced tightness are essential to guarantee safe operation and reliable sealing over time.

- a. Initial Setup

Lay a soft protective mat at the bottom of the vessel, then place the agitator on it. Lift the tank lid to the correct position and mount the seal on the agitator shaft. After that, raise the agitator and connect it to the reducer’s output shaft. Secure the connection firmly with the check nut and check bolt. -

b. Alignment and Testing

Adjust the agitator shaft and seal for proper concentricity and vertical alignment, following the technical specifications. Rotate the shaft slowly by hand first. It must move smoothly and without resistance. Only when this has been confirmed should the motor be started.

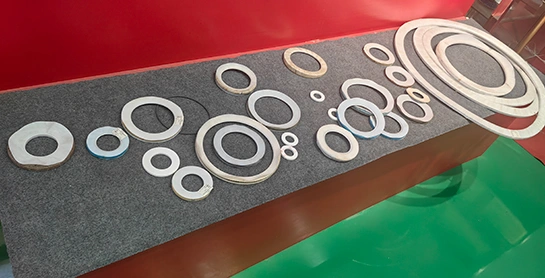

The choice of gasket depends on the medium being handled, its type, concentration, and working temperature. Both the material and the way it is applied must fit the process requirements. At present, we supply several options:

- PTFE-wrapped asbestos gasket

- PTFE-wrapped asbestos gasket with corrugated stainless steel

- PTFE-wrapped non-asbestos gasket with corrugated stainless steel

- PTFE-wrapped rubber gasket

Welding directly on the outer surface of a glass lined vessel is not allowed.

When it is necessary to weld nozzles, lugs, or supports, electric welding should be used along with proper cooling. Gas welding is strictly forbidden. If welding has to be done close to the glass lining, make sure to cover both the lining and the nozzles. This will protect them from sparks and welding slag, since even a small splash can easily cause damage.

Jiangsu Gongtang

Jiangsu Gongtang