- GT88 glass has a good resistance to corrosion and in tests with boiling hydrochloric acid, it lasted nearly three times longer than ordinary glass. In hot sodium hydroxide solution, its resistance was more than twice as strong.

- The glass also features protection against abrasion, adhesion, and mechanical shock. Equipment lined with GT88 is easier to clean, needs less maintenance, and ensures reliable long-term performance.

- GT88 bonds firmly to carbon steel, creating a smooth and even surface. The glass lining has a distinctive blue finish that reflects both its durability and reliable performance.

- GT88 is manufactured using advanced electric furnace control systems that meet international standards. Every batch of enamel powder is subject to strict quality checks, which helps to minimize defects and ensure consistent performance.

- GT88 is made with local raw materials but follows an imported glass formula, giving it the same physical and chemical properties as original imported glass. Over years of use, it has shown reliable performance, and customers with strict requirements value its strong corrosion resistance. The warranty for GT88 follows international standards, giving customers peace of mind when selecting equipment lined with this glass.

| Indicators | Unit of Measurement | Test Standard | Reference Value | Test Result |

| Corrosion resistance in boiling HCl | g/m²·d | GB/T 7989 | ≤ 1.6 | 0.4 |

| Corrosion resistance in hot NaOH | g/m²·d | GB/T 7988 | ≤ 5.0 | 1.5 |

| Mechanical shock resistance | 10⁻³ J | GB/T 7990 | ≥ 220 | 290 |

| Thermal shock resistance | °C | GB/T 7987 | ≥ 200 | 213 |

Note: All test results shown above were obtained from GT88 glass specimens in accordance with the relevant national testing standards.

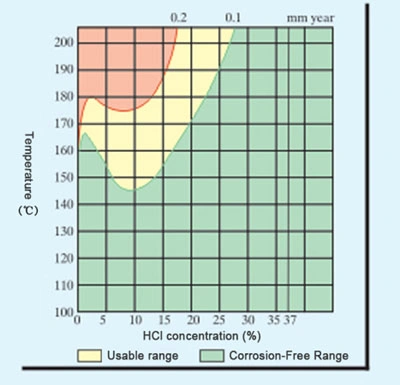

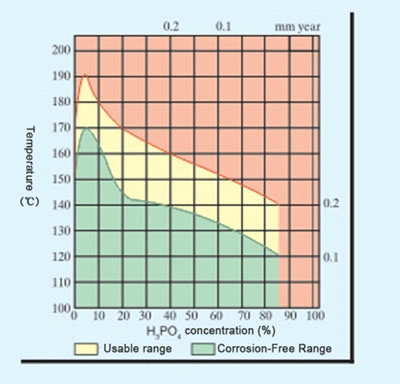

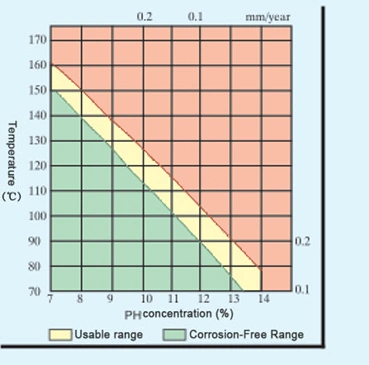

The chart below shows the typical corrosion levels of glass lined equipment when exposed to acids and alkalis, based on continuous long-term testing.

- When the corrosion rate is less than 0.1 mm/year, the glass lining can remain fully effective for about five years.

- At a rate of 0.1–0.2 mm/year, the service life usually ranges from two to five years.

- If the rate reaches 0.2 mm/year or higher, the expected lifespan decreases significantly, often to two years or less.

Among all the acidic substances used in the chemical industry, hydrochloric acid is the most common, but it is also one of the most corrosive to equipment materials. GT88 glass lining offers strong resistance to this liquid, as shown in the table. The corrosion resistance changes quite a bit at low concentrations. It reaches its highest point at around 1%, then drops to the lowest level near 10%. At concentrations above 10%, the resistance rises sharply again. The same trend can also be observed with hydrobromic acid, iodic acid, and chloroacetic acid.

The way glass lining resists corrosion in phosphoric acid is very different from its behavior in other acids. In most acids, corrosion resistance improves as the concentration increases. With phosphoric acid, however, the opposite happens, the higher the concentration, the lower the resistance. Because phosphoric acid often contains fluoride impurities, corrosion tests need to be carried out over a longer period, usually at least a week, to get an accurate evaluation of performance.

At low concentrations, glass lining provides its highest level of corrosion resistance against these acids. Once the concentration reaches around 20%, however, the resistance drops to its lowest point. Beyond this point, as the concentration continues to increase, the resistance improves again. The same trend also applies to sulfurous acid and nitrous acid. Acetic acid is included here as a representative example of an organic acid.

At room temperature, GT88 glass lining can withstand alkalis at any pH level. However, as the temperature rises, its corrosion resistance decreases. For highly concentrated sodium hydroxide or potassium hydroxide (pH 14 or higher), the safe operating limits are:

- 66 °C at 10% concentration

- 60 °C at 20% concentration

- 57 °C at 30% concentration

- 54 °C at 50% concentration

In neutralization processes, when the pH is around 13, GT88 can operate at temperatures up to 100 °C. When using liquid or solid alkalis, they should be placed in the center of the reactor and stirred carefully. This prevents localized overheating and adhesion of the reactants to the glass lining, which could cause damage. Metal-organic compounds (except fluorides) do not corrode glass lining under normal conditions.

Below the boiling point, GT88 glass lining shows strong resistance to both liquid and vaporized water. Above boiling, it can be used safely up to 150 °C. However, it is important to note that high resistance to acids does not necessarily mean equally strong resistance to water.

For salts (except those containing fluorides), the level of corrosion largely depends on the pH of the solution. For example, sodium chloride on its own is neutral, but once dissolved in water the solution becomes corrosive, with water acting as the medium. The same is true for aluminum chloride, which releases chloride ions when in solution. Detailed data on how GT88 glass lining performs in these salt solutions can be found in the related charts.

In most cases, trace amounts of fluorides can be present in liquids, so extra caution is required during operation. Fluorides are commonly found in phosphoric acid, phosphorus compounds, hydrochloric acid, and regenerated sulfuric acid. For this reason, corrosion testing should always be carried out before using these solvents.

GT88 glass lining is highly resistant to most organic solvents when used below the maximum operating temperature. The main concern is with low-conductivity solvents such as methane, xylene, toluene, benzene, and heptane, since these are more likely to cause static buildup. When these are used, either alone or mixed with other substances, static electricity can build up between different liquids, between liquid and vapor phases, or between the liquid and the vessel walls. Sparks released by this static charge may ignite vapors and cause an explosion, which can damage the glass lining by cracking it or forming pinholes. Because of this, extra care is needed when handling these solvents.

Jiangsu Gongtang

Jiangsu Gongtang