White enamel glass lined equipment

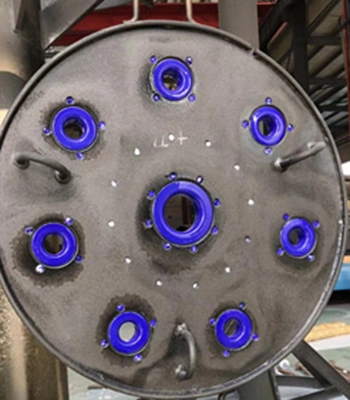

White enamel glass lined multi-nozzle reactor cover

White enamel glass lined reactor

White enamel glass lined reactor cover

White enamel glass lined heat exchange tubes

White enamel glass lined manway cover

Multi-nozzle photocatalytic glass lined reactor

Non-standard glass lined equipment refers to vessels designed and manufactured according to specific customer requirements. Compared with standardized designs, these customized solutions offer greater flexibility and adaptability to meet unique process needs. They can be engineered in a variety of structures to suit different production processes and are widely applied in industries such as petroleum, chemicals, light industry, pharmaceuticals, and food.

When selecting or designing non-standard glass lined equipment, the following factors should be carefully considered:

- Process requirements: The structure, dimensions, and pressure rating should be determined according to the characteristics of the process.

- Operating environment: The level of corrosion resistance and pressure performance should be selected based on the properties of the medium and environmental conditions.

- Budget considerations: Equipment costs should be matched reasonably while ensuring process needs and safety requirements are met.

Non-standard glass lined lengthened type reaction tank

Tank body with welding baffle

Large size reactor with more side nozzles

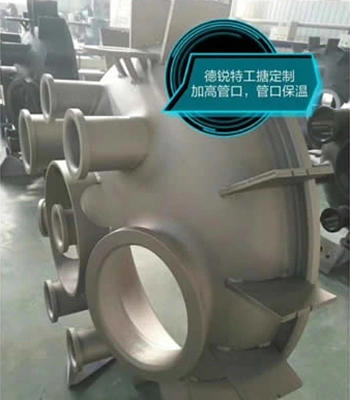

Head cover with increased height nozzle

Customized multi-nozzle glass-lined reactor

Reactor with non-standard head cover

Glass lined flat cover reactor

Glass lined reactor with four column rack