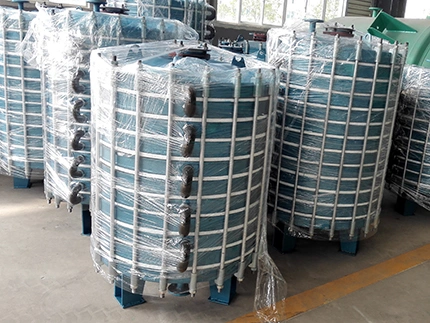

Glass Lined Plate Heat Exchanger

Corrosion-resistant plate condensers for condensing and cooling corrosive media

The glass lined plate heat exchanger is designed for condensing and cooling highly corrosive fluids and is widely used in chemical, pharmaceutical, pesticide, and light industries. When fitted with food-grade rubber gaskets, it can also be applied in food processing.

Because the flow channels are narrow and the liquid velocity is high, the heat transfer rate is greatly improved. The unit is made up of multiple independent metal plates, which makes installation and disassembly simple. If one plate is damaged, it can be replaced individually without affecting the rest of the system, helping extend the service life of the equipment.

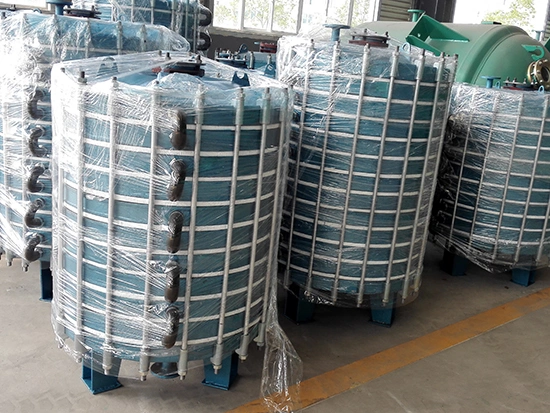

- The glass lined plate heat exchanger can be used in high-vacuum distillation and evaporation systems. It reduces pressure drop and helps prevent common issues such as enamel cracking or leakage.

- By using thinner metal plates, the cooling water flows faster, which boosts overall performance. The six-port distribution design helps distribute fluids evenly across the surface, raising the heat transfer rate by over 50% compared with standard condensers of the same area. In addition, the smooth glass-lined surface and improved flow conditions reduce scaling, helping to maintain consistent performance over time.

- Each heat exchanger is equipped with 10 mm gaskets that show minimal expansion or shrinkage under varying conditions. This makes them suitable for high-pressure operation and reliable sealing in vacuum environments.

- The heat exchange area can be adjusted by adding or removing plates, which allows the glass lined plate heat exchanger to adapt to different process requirements without major modifications.

Jiangsu Gongtang

Jiangsu Gongtang