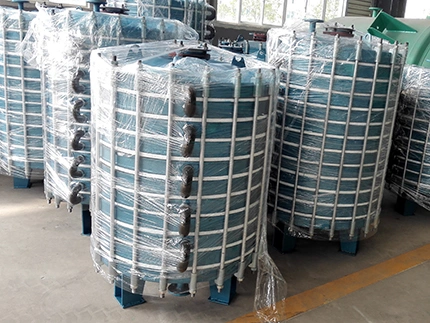

Glass Lined Shell and Tube Heat Exchanger

Corrosion-resistant tubular condensers for heat transfer processes in chemical and pharmaceutical industries

In chemical and pharmaceutical plants, processes such as boiling, condensation, and heat transfer often involve corrosive or demanding media. Glass lined shell and tube heat exchangers are built to meet these challenges by combining a steel shell, which provides the strength to withstand pressure, with glass-lined tubes that resist corrosion and maintain a smooth, non-reactive surface. The combination of steel and glass lining allows the exchanger to operate consistently while keeping the processed materials clean and unchanged.

Thanks to advanced manufacturing technology originally introduced from Japan, these exchangers achieve heat transfer efficiency several times higher than that of conventional plate exchangers. They also overcome common problems seen in plate-type designs, including slow fluid flow, risk of enamel damage, and limited ability to operate under vacuum conditions. By offering stable performance, high durability, and efficient heat transfer, glass lined shell and tube heat exchangers are widely used in demanding chemical and pharmaceutical applications that require both safety and consistency.

Jiangsu Gongtang

Jiangsu Gongtang