Mechanical Seal for Glass Lined Reactor

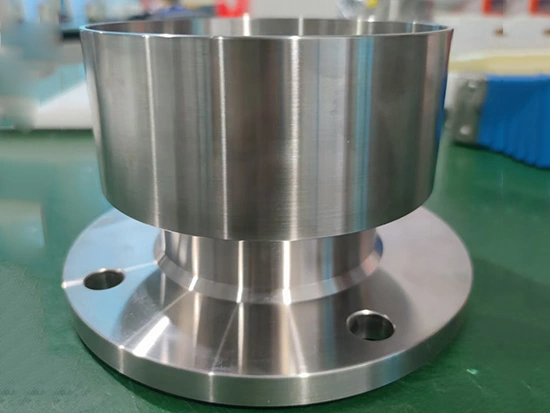

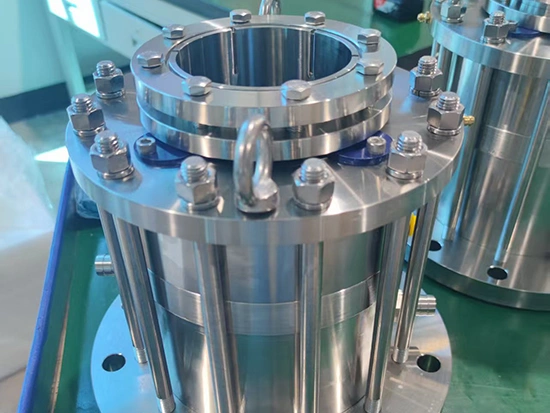

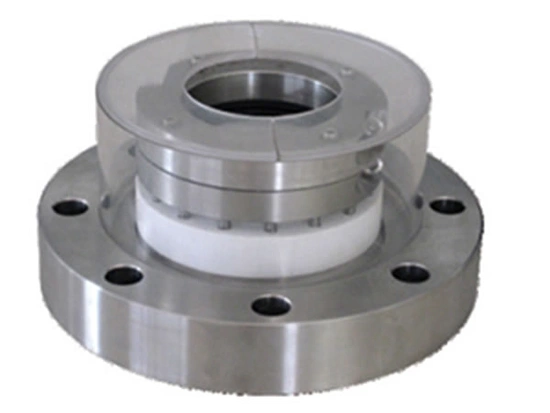

Single and double mechanical seals for glass lined reactors

Mechanical seals for glass lined reactors are used to prevent leakage where the agitator shaft passes through the reactor wall. If no sealing device is installed, process media may escape or, in cases where the internal pressure is lower than atmospheric pressure, air may enter the reactor. By using mechanical seals, we ensure that the operation remains safe and that the process is properly contained. These seals are the most common choice for glass lined reactors because they provide reliable performance, minimal leakage, and long service life.

Different types of mechanical seals can be supplied, including GMP-compliant dry seals, so they can be adapted to the specific requirements of each process. The main options are listed below:

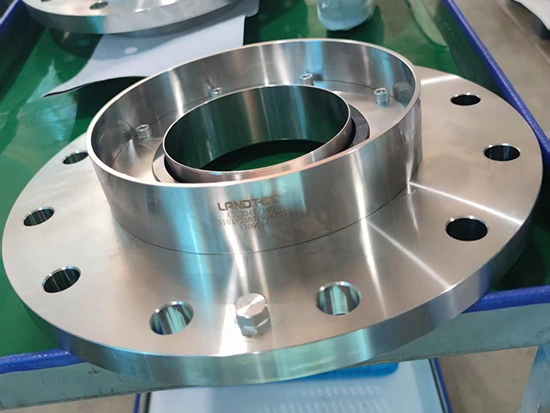

These seals are suitable for handling corrosive and granular media. They are assembled with standardized components, can be used in different directions of transmission, and offer reliable adaptability.

Technical Parameters- Operating pressure: 0.1–0.6 MPa

- Operating temperature: -10°C to 180°C

- Maximum shaft speed: ≤ 2 m/s

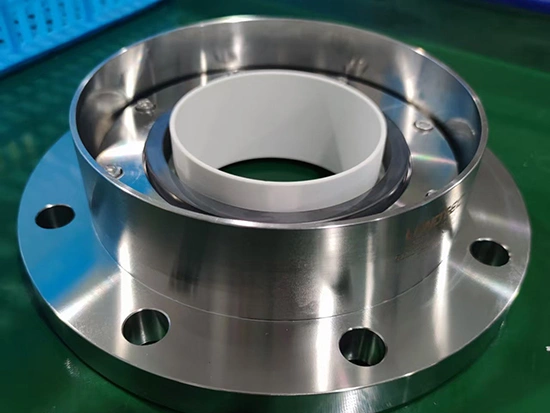

Designed to handle acids, alkalis, and other aggressive substances. These mechanical seals ensure reliable sealing performance under a wide range of operating conditions.

Technical Parameters- Operating pressure: 0–1.0 MPa

- Operating temperature: -40°C to 120°C (up to 250°C with cooling water tank)

- Maximum shaft speed: ≤ 2 m/s

End face seals with a cartridge structure can run in either direction. A built-in leakage collector prevents contamination of the materials during operation.

Technical Parameters- Operating pressure: 0–1.0 MPa

- Operating temperature: -40°C to 180°C

- Maximum shaft speed: ≤ 2 m/s

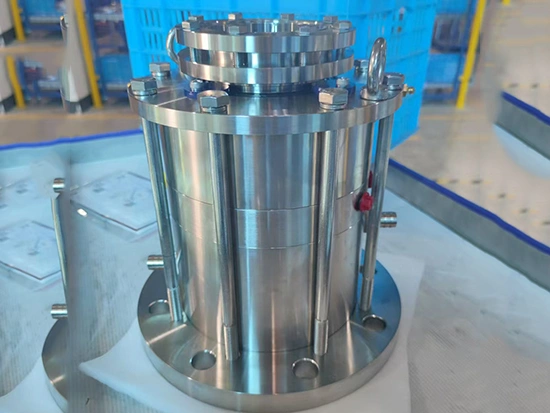

These seals are suitable for gaseous media that do not contain suspended particles, except for hydrogen fluoride (HF).

Technical Parameters- Operating pressure: 0–10.4 MPa

- Operating temperature: -10°C to 120°C

- Maximum shaft speed: ≤ 1.5 m/s

Our engineers provide expert guidance on corrosion-resistant glass-lined reactors, tanks, and customized process equipment for chemical, pharmaceutical, and industrial applications.

Jiangsu Gongtang

Jiangsu Gongtang